Servicing UK Dredgers– 3D Scanning, Ultrasonic Thickness Measurements, Photographic survey and CAD -Part 2

Over the past twelve months, Digital Dry Dock has been using its 3D laser scanning technology to assist with dredging vessels refit and repair in multiple locations across the UK.

Our technology makes maintenance and safety inspections of vessels much easier and quicker than using traditional hand-measuring techniques.

In this blog, we share the second of two projects with you in which we saved our clients time and expense by using our 3D scanning technology on their dredging vessels.

Project 2: Arco Dart

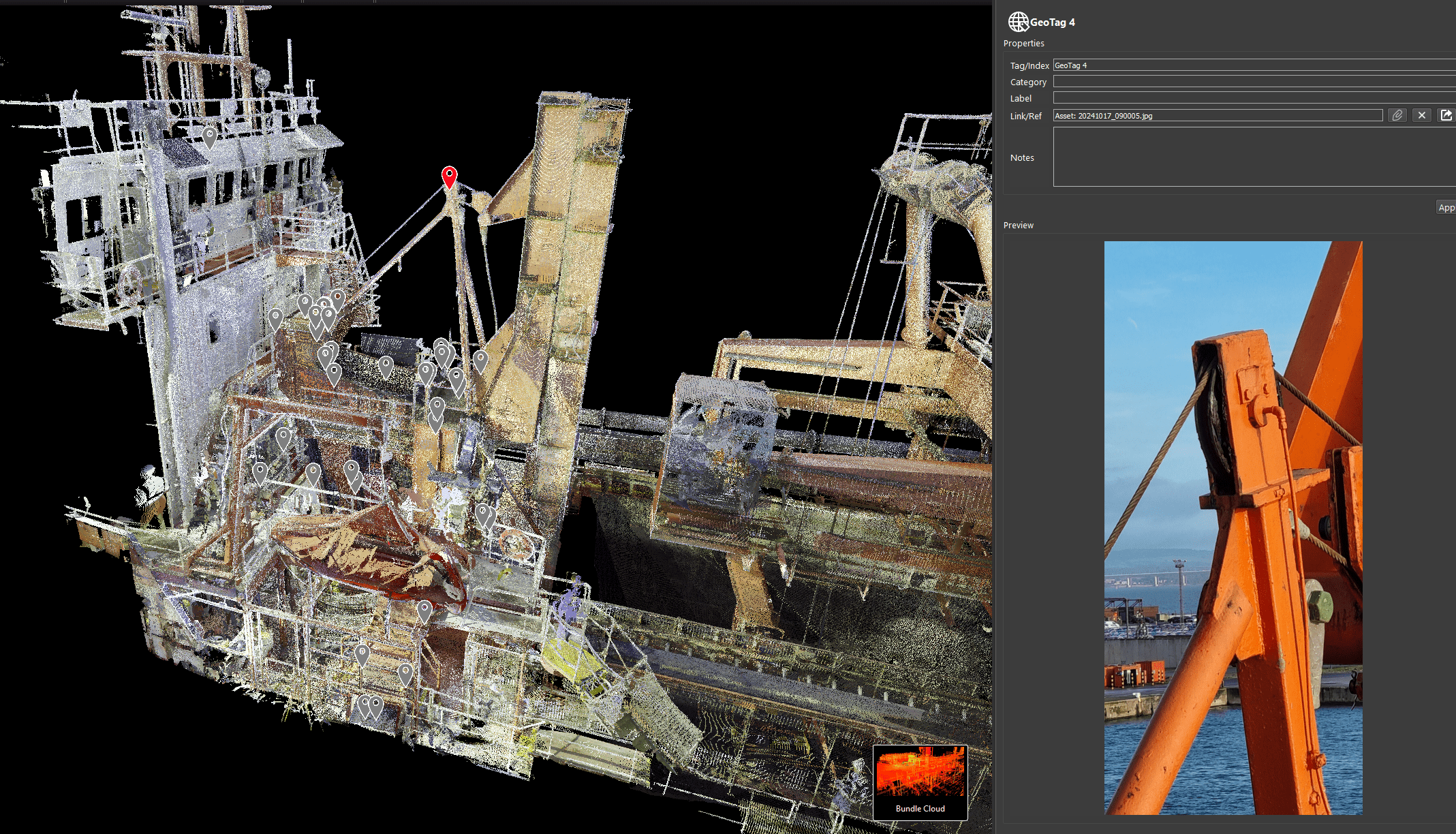

Later in the year, Digital Dry Dock had the opportunity to assist Heidelberg Materials UK with their vessel, the Arco Dart, at Avonmouth Docks in Bristol. This project focused on reverse engineering key vessel components, including the loading tower, reject chute, and dredging ‘slipper’, to support the design and fabrication of new replacement parts.

Phase 1: Scanning of the loading tower and reject chute

To ensure the accurate replication of these essential components, we conducted a high-resolution 3D scan using the Leica RTC360 3D Laser Scanner. The scanning process captured an as-built digital model, which was then used to create a 3D surface model and digitise the original fabrication drawings.

This data enabled precise reverse engineering, ensuring the new components would be a perfect fit when installed on the vessel.

Phase 2: 3D Scanning of Californian Draghead dredging ‘slipper’

The Arco Dart’s Californian Draghead dredging ‘slipper’ also required replacement. Using the same Leica RTC360 3D Laser Scanner, we captured an accurate surface model.

With these 3D models and 2D sectional drawings, Heidelberg Materials UK had the precise data needed to manufacture a new dredging ‘slipper’ with confidence.

Final result

By leveraging our 3D scanning and CAD expertise, we helped Heidelberg Materials UK modernise critical components on the Arco Dart without relying on outdated or incomplete original fabrication drawings. This ensured a cost-effective, precise, and efficient approach to vessel maintenance and upgrades. We were able to complete the entire project, with one day spent on site and CAD drawings delivered within one week.

Get in touch

These projects demonstrate how Digital Dry Dock’s advanced 3D scanning technology can streamline maintenance, reduce downtime, and improve asset management for dredging vessels across the UK.

For inquiries about similar projects, contact us at Digital Dry Dock.