Servicing UK Dredgers– 3D Scanning, Ultrasonic Thickness Measurements, Photographic survey and CAD

Servicing UK Dredgers– 3D Scanning, Ultrasonic Thickness Measurements, Photographic survey and CAD

Over the past twelve months, Digital Dry Dock has been using its 3D laser scanning technology to assist with dredging vessels refit and repair in multiple locations across the UK.

Our technology makes maintenance and safety inspections of vessels much easier and quicker than using traditional hand-measuring techniques.

In this blog, we share the first of two projects with you in which we saved our clients time and expense by using our 3D scanning technology on their dredging vessels.

Project 1: A.I Avocet

Last year, Digital Dry Dock had the privilege of working with Aggregate Industries on their vessel, the A.I. Avocet. This project required state-of-the-art scanning and inspection services to support ongoing maintenance and ensure the suction dredger’s optimal performance. With work conducted at both A&P Falmouth and Portsmouth, the project involved two key phases:

Phase 1: 3D Scanning of pump room and inboard suction pipe

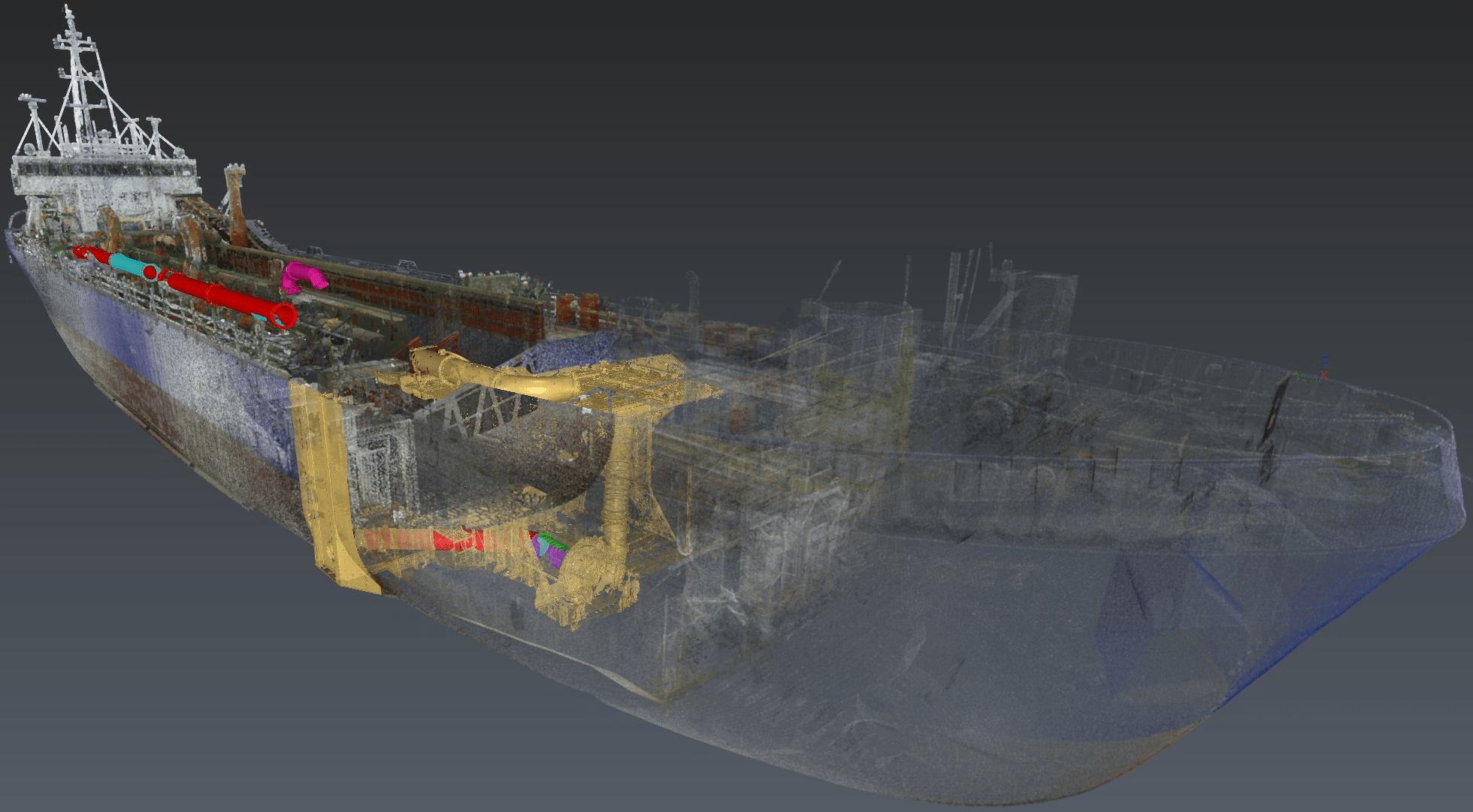

Using the Leica RTC360 3D Laser Scanner, we completed the scanning in just half a day on-site in Falmouth. The captured data was processed and delivered within a day, providing a fully registered point cloud that offered Aggregate Industries a detailed digital representation of the pump room and suction pipe layout. This in turn allowed routine maintenance along with improvements to be made to the pipe.

Phase 2: Whole vessel scanning and ultrasonic thickness measurements of dredge pump

The Leica RTC360 3D Laser Scanner and Cygnus 1 Ex UT Gauge were instrumental in completing this task. Over two days on-site, we scanned the entire vessel, capturing a colourised point cloud and high-resolution 3D imagery. The photos have since been used for asset management and can be referred to for future upgrades or engineering works.

For the dredge pump casing, ultrasonic thickness measurements were meticulously taken to evaluate material thickness and identify potential wear or corrosion. The data was processed and compiled into a detailed report, delivered within one week.

Final result

The A.I. Avocet plays a vital role in Aggregate Industries’ operations, and keeping it in peak condition is essential. Our precise 3D scanning and UT measurement services provided the necessary data to support informed maintenance and repair decisions, ensuring the vessel remains reliable and efficient.

This project demonstrates our commitment to delivering cutting-edge solutions tailored to the maritime industry’s unique challenges.

For inquiries about similar projects, contact us at Digital Dry Dock.